Welcome to my Series III Restoration Site

Range Rover Restoration, April 2023

The Range Rover is continuing to be worked on in my absence.  The chassis and shell have been separated and the exterior panels have been going through their preparation for repainting, including the removal of what little corrosion there was, sorting a few small dents and welding up the hole in the roof that was made for the first owner’s car phone antenna.  The doors were in unusually good order, the roof rust free and the bonnet nearly so.  The rear corners were only a little rusted in the spot welded flange joint either side of the lower tailgate, needing relatively little work to rectify.  The tailgate just needed repair around the two holed for the number plate lights, the rest also rust free.  The wings, doors, lower tailgate and rear corners have all been polyurethane primed and rubbed back after guide coating (a light spray of black paint that reveals high and low spots for further filling or fettling before a further coat of priming and painting).  By the time this update was written, they may have been joined by the remaining outer panels.

The Range Rover is continuing to be worked on in my absence.  The chassis and shell have been separated and the exterior panels have been going through their preparation for repainting, including the removal of what little corrosion there was, sorting a few small dents and welding up the hole in the roof that was made for the first owner’s car phone antenna.  The doors were in unusually good order, the roof rust free and the bonnet nearly so.  The rear corners were only a little rusted in the spot welded flange joint either side of the lower tailgate, needing relatively little work to rectify.  The tailgate just needed repair around the two holed for the number plate lights, the rest also rust free.  The wings, doors, lower tailgate and rear corners have all been polyurethane primed and rubbed back after guide coating (a light spray of black paint that reveals high and low spots for further filling or fettling before a further coat of priming and painting).  By the time this update was written, they may have been joined by the remaining outer panels.

The inner shell has been more closely checked over.  As anticipated, the front inner wings and head light mountings will be replaced, along with the sills, rear cross member and boot floor.  The front left foot well and outboard edges of the rear wheel arches will have repair strips let in but don’t need outright replacement.  I haven’t heard what the plan is for the spot welded seams of the A-pillars to bulkhead, but the restorers were keen to stress that it wasn’t a big problem.

The inner shell has been more closely checked over.  As anticipated, the front inner wings and head light mountings will be replaced, along with the sills, rear cross member and boot floor.  The front left foot well and outboard edges of the rear wheel arches will have repair strips let in but don’t need outright replacement.  I haven’t heard what the plan is for the spot welded seams of the A-pillars to bulkhead, but the restorers were keen to stress that it wasn’t a big problem.

I got the parts for the transmission oil cooler and have since also found a full set of used air conditioning pipes, hoses and brackets for a contemporary 300Tdi Discovery, slightly different in configuration to the incomplete pipes I got with the rest of the system years ago from another Discovery. Â Hopefully, this will allow them to make up a full set, and this time with the dryer bottle in the engine bay instead of behind the front grille as it currently sits (awkward to service and not helpful to cooling airflow through the condenser and radiator).

The chassis has been stripped of all other parts and is waiting for blasting and painting.  I don’t expect it to need any repairs.  The rear suspension has been dismantled for the same treatment, and the rear axle will get cleaned up before an inspection of the diff pan determines whether the small rust hole can be repaired or the pan needs replacement.  The front axle and suspension were waiting to be dismantled last week, but may have been done by now.  I still expect to retain the existing springs and hope to retain the dampers, depending on their condition.  I have no idea if the Boge strut works, but with the rear spring that were fitted when I bought the car, it doesn’t really matter as the strut is usually redundant.  I’ll have to remember to ask about its serviceability on their next update.

The chassis has been stripped of all other parts and is waiting for blasting and painting.  I don’t expect it to need any repairs.  The rear suspension has been dismantled for the same treatment, and the rear axle will get cleaned up before an inspection of the diff pan determines whether the small rust hole can be repaired or the pan needs replacement.  The front axle and suspension were waiting to be dismantled last week, but may have been done by now.  I still expect to retain the existing springs and hope to retain the dampers, depending on their condition.  I have no idea if the Boge strut works, but with the rear spring that were fitted when I bought the car, it doesn’t really matter as the strut is usually redundant.  I’ll have to remember to ask about its serviceability on their next update.

Range Rover Restoration

The Range Rover has been slowly deteriorating ever since I left the UK eight years ago.  Well, it was deteriorating long before that too, but leaving it half stripped down for restoration in a garage that isn’t as well ventilated as I’d like … [Continue reading]

109 Salisbury ATB and 4.1:1 Gears

Well, I bit the bullet last summer and ordered an Ashcroft Transmissions ATB for the Salisbury axle, a new product from them that has been on the cards for them for the last couple of years. Â This is made to replace the Salisbury 8HA as used in … [Continue reading]

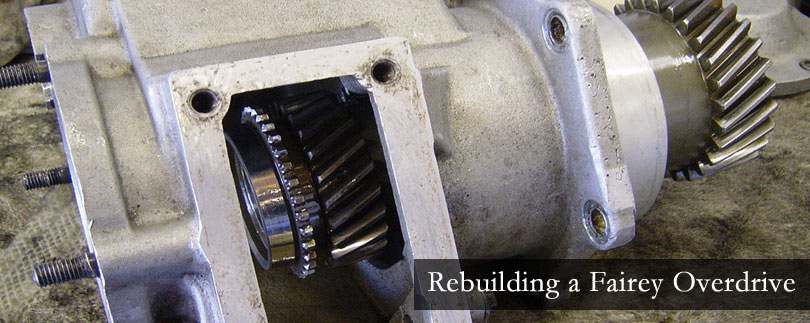

New Fairey Overdrive

A few years ago, for a project I could do overseas and also to have a spare, I bought another Fairey overdrive.  It was bought unseen as a noisy but serviceable unit.  Yeah… I spent a couple of months of late 2022 stripping and inspecting the … [Continue reading]

Uprated Alternator

I have long wanted a better alternator than the standard 65A unit to be able to rapidly recharge both batteries, run the various lights and heaters in winter or run the winch without rapidly depleting the battery, and had planned in the future on … [Continue reading]

Social